Bakery industry

INOXPA has a division that specialises in processes for the bakery and pastry industry, supported by first-class engineering with extensive knowledge and vast experience with world-leading multinational companies. We offer customised solutions for both solids and liquids in this sector.

We develop complete medium and large turnkey projects, including equipment, from receiving and storing raw materials, through the pneumatic transportation of solids and micro ingredient dosing, to dosing in the mixers.

Our extensive network of subsidiaries and distributor partners ensures we are close to customers and can guarantee rapid and effective technical service throughout the installation’s useful life, i.e. from project development through to implementation and start-up, and during post-sales.

Products and applications

Products and applications

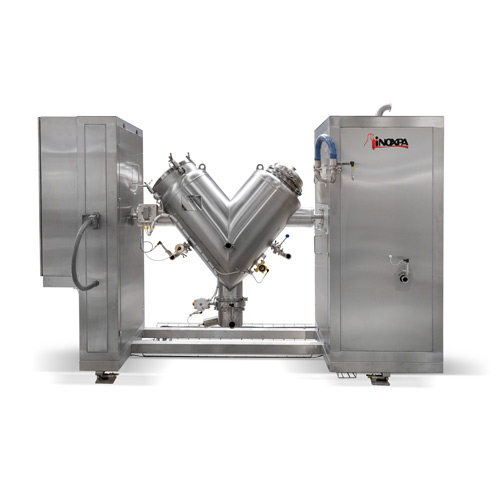

Solutions for solids

When it comes to solids, we can supply silos for raw materials, big-bag or sack unloading stations and systems for minor and micro ingredient dosing.

We can also supply hoppers, platforms, sieving machines, and pneumatic transportation systems for the diluted or dense phases.

We can certify our installations in accordance with the ATEX and FDA directives by conducting the relevant risk analysis and installing duly certified components.

Solutions for liquids

The bakery industry also requires equipment and installations for liquids, such as sourdough plants, in order to be able to produce a traditional and higher quality product on an industrial scale.

Other equipment needed in this industry include bread cream plants for reprocessing bread and pastry to add it to the process in liquid form, and plants for storing and dosing liquid yeast.

Lastly, other essential equipment in this sector include PIG product recovery systems and CIP systems to automatically clean the entire system correctly.

Customer benefits

-

Commitment, reliability and safety

- We can apply the know-how we have accumulated over the years from working with first-class customers worldwide and our pilot plant is available when developing new products and optimising processes for our customers.

- We include FAT tests in our projects before the equipment is delivered and started up at the customer’s installations to ensure the equipment functions correctly or can be installed as quickly as possible.

-

Proprietary, high-quality manufacturing

- We are known for our meticulous approach when designing our equipment and plants, ensuring that each detail complies with the most stringent industry standards and regulations.

- The key to our success is based on proprietary equipment and component manufacturing, which enables us to achieve the best possible outcome and ensure the highest quality food products.

-

High-end technology and automation

- We design and manufacture technologically-advanced equipment and plants with the corresponding certifications to enable work under the most demanding conditions.

- We can adapt the level of automation to customer needs, with the option of integrating it into existing systems in the plant, and complying with Industry 4.0 requirements.

Case studies

Find out how we help both small and large companies of this industry achieve their goals.

-

Solids and liquids dosing for pastry production

A fully automated system for dosing flour, sugar and water at the points of use for sourdough production.

-

Sourdough production plant

Design, manufacture and installation of a fully automated sourdough production and dosing plant complemented with CIP cleaning system.

-

Ingredient dosing for pastry production

The design, manufacture, supervision and start-up of equipment for handling solids and liquids for a major bread manufacturer.

Brochure

What does INOXPA offer the food industry?

Find out about INOXPA’s products and equipment for the food industry.

Download

Request information

Bakery industry