Product Recovery System SILPIG

10/09/2014

.jpg)

Product recovery system SILPIG is ideal equipment for the recovery of the viscous product remaining in the pipeline which resultant to reduction in wastage, greater efficiency and increase in profitability.

INOXPA Product Recovery System SILPIG is designed to recover the entire product remaining in a pipeline at the end of the transfer process by the help of a PIG (spherical shaped). The SILPIG design comprises a launcher, a receiver, a PIG, two position detectors (one at the side of launcher and another at the receiver), four automatic butterfly valves and 2 KH multi-way valves.

Mechanism behind product recovery through SILPIG is to put the sphere at the launch position with the help of normal compressed air and when the product transfer completes the PIG return back at the receiver position along with the recovery of product residual. At the end of the recovery process the PIG at the receiver is cleaned along with the system during the CIP normal routine and PIG is again located at the launcher for the next production run.

Applications of SILPIG:

- Preparation of confectionary cream’s.

- Preparation of chocolates.

- Preparation of marmalades.

- Preparation of gels, creams and other body care products for cosmetic industry.

Read here for more details:

Contact

Other news

-

30/07/2025

30/07/2025Integral solutions that make the difference

INOXPA have been offering complete, customised solutions for years. We take care of the entire engineering, automation and assembly process.

Systems -

09/07/2025

09/07/2025CMC mixing systems

INOXPA’s CMC mixing systems are efficient, versatile, and customisable solutions for the dispersion of hydrocolloids across various industries.

Systems -

16/06/2025

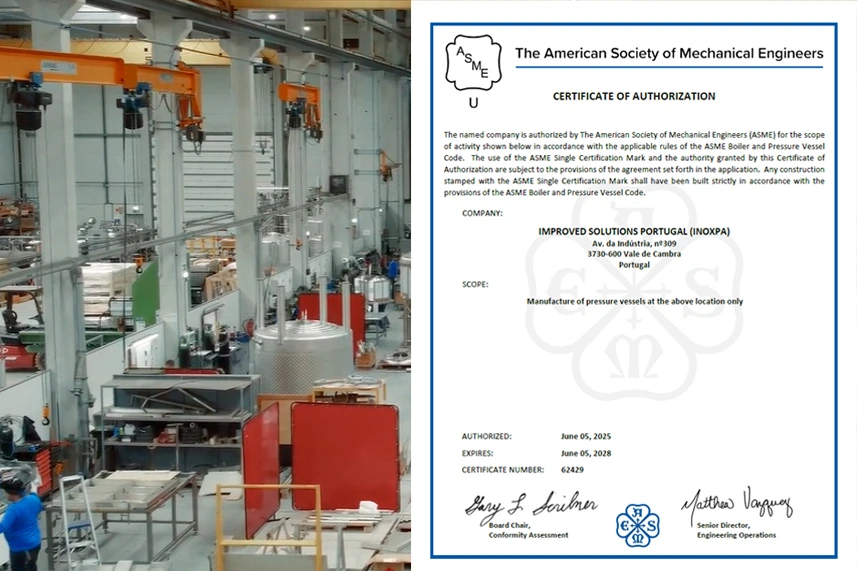

16/06/2025U-Stamp certification

This certification strengthens our position as a trusted supplier in industries where quality and compliance with standards is essential.