INOXPA Tank Bottom Mixer ME 6100

12/12/2014

.jpg)

Tank Bottom Mixer ME-6100 is a high shear mixer used by pharmaceutical and cosmetics industry for their N number of applications. It is hygienically designed for use in the processes of dispersion, emulsification, homogenisation and disintegration in the pharmaceutical industry. Due to the design, these mixers are easily cleanable and can be sterilised (CIP/SIP) after the production process.

Tank bottom mixers are efficient in mixing of highly viscous products and compatible to work with anchor type agitators.

Salient Features of Tank Bottom Mixer ME 6100

High shear, particle size reduction to less than 100 microns.

Access to the mechanical seal from the inside of the tank.

Stator replaced without disassembling the mixer.

Different easily interchangeable head models.

Standard single sanitary mechanical seal.

Standard flange for tank bottom assembly.

Slotted head.

Motors: IEC B5, IP 55, F-class insulation.

Applications of Tank Bottom Mixer

Preparation of ophthalmologic or contact lens solutions.

Preparation of syrups.

Preparation of pill coatings.

Preparation of creams and lotions.

Preparation of injections.

Contact

Other news

-

30/07/2025

30/07/2025Integral solutions that make the difference

INOXPA have been offering complete, customised solutions for years. We take care of the entire engineering, automation and assembly process.

Systems -

09/07/2025

09/07/2025CMC mixing systems

INOXPA’s CMC mixing systems are efficient, versatile, and customisable solutions for the dispersion of hydrocolloids across various industries.

Systems -

16/06/2025

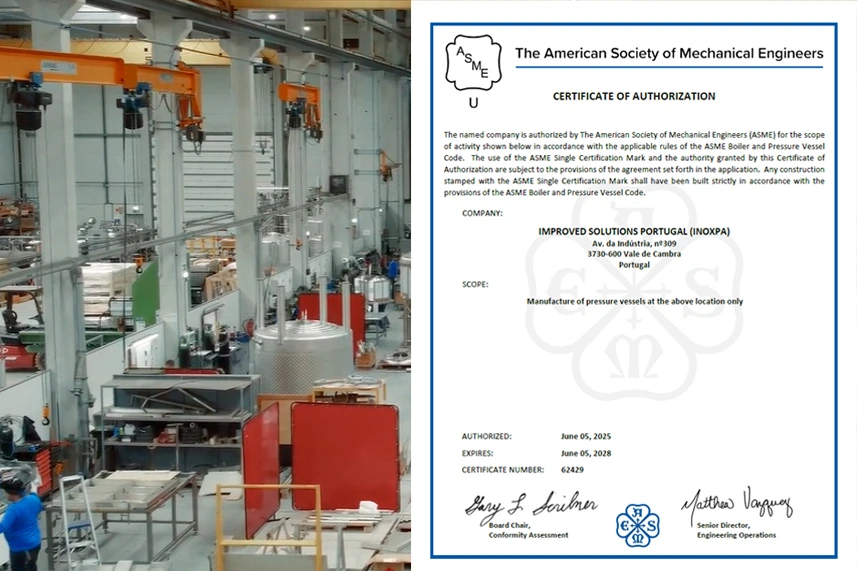

16/06/2025U-Stamp certification

This certification strengthens our position as a trusted supplier in industries where quality and compliance with standards is essential.