Horizontal Blender MH-20 MH-26

05/06/2015

.jpg)

Mixing is a very critical process in the food, dairy, pharmaceutical and cosmetics because the desired final product is purely dependent on the mixing of the product and its attributes.

Hence, the experts always suggest using the proper equipment for an optimum mixing.

INOXPA upon analysing the aspects of mixing manufactures a wide range of mixing solutions for the food, dairy, pharmaceuticals and cosmetics to get the desired quality of the final product.

Horizontal Blender MH-20 / MH-26 is a blender designed and manufactured by INOXPA for ideal mixing of the product that ensure the desired final quality of the product. The horizontal blender is a perfect solution for the dissolution of powder products into a circulating liquid. The unit is limited to the suction of small amount of solids as the blender has no table for bags and the hopper is smaller than that of the table blender.

INOXPA clients are using horizontal blender for wide range of applications in the industries such as:

Dairy Industry:

Preparation of butter milk.

Preparation of flavoured milk.

Preparation of powdered milk.

Pharmaceuticals:

Blending of active ingredients of a drug.

Preparation of syrups.

Preparation of glucose.

Preparation of brine.

Food & Beverage Industry:

Preparation of sugar syrup.

Preparation of coconut milk.

Read for more details:

Contact

Other news

-

27/10/2025

27/10/2025Discover INOXPA’s Partner Portal: efficiency, simplicity and control

We present the Partner Portal, a platform designed to make two-way interaction between customers and INOXPA easier.

-

25/09/2025

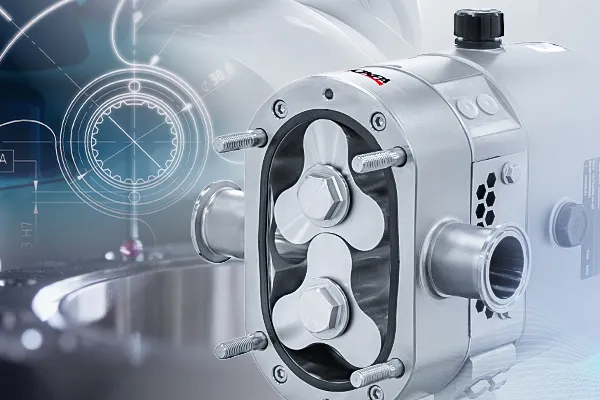

25/09/2025UltiLobe: the ultimate lobe pump

UltiLobe is the new generation of rotary lobe pumps with hygienic design, that expands the INOXPA´s portfolio of positive displacement pumps.

Pumps -

30/07/2025

30/07/2025Integral solutions that make the difference

INOXPA have been offering complete, customised solutions for years. We take care of the entire engineering, automation and assembly process.

Systems