Flexible Impeller Pump

11/12/2015

RF Flexible Impeller Pump, due to its design, is widely popular among the food, dairy, pharmaceutical, cosmetics and wine-making industries. The eccentric shape of the pump housing enables it to create vacuum in suction side which results in enlarging the volume between the blades to suck the product and at the discharge side the blades bend to reduce the volume between them and cause the smooth discharge of the product.

RF Flexible Impeller Pump is the best solution for a gentle transfer of the product without altering its properties. For instance, in the case with other pumps, pumped products such as cream, wine, gel etc. may increase or decrease the viscosity due to heat produced during the transfer. Hence, the competitive advantage of RF Flexible Impeller Pump is to transfer the products without interfering in viscosity of the product.

The pump design makes it also reversible and self-priming which enables it to suck product from maximum height of 5 meters.

INOXPA flexible impeller pump is designed and manufactured to handle both low and high viscosity products containing particles or gases.

Application of Flexible Impeller Pump

Transfer of dairy products

Transfer of edible oils

Transfer of wine

Transfer of jams, marmalade, custards

Transfer of cosmetics products such as soap, gel, creams etc.

In case of any query related to product, feel free to get us on inoxpaindia.sales@inoxpa.com !

Contact

Other news

-

30/07/2025

30/07/2025Integral solutions that make the difference

INOXPA have been offering complete, customised solutions for years. We take care of the entire engineering, automation and assembly process.

Systems -

09/07/2025

09/07/2025CMC mixing systems

INOXPA’s CMC mixing systems are efficient, versatile, and customisable solutions for the dispersion of hydrocolloids across various industries.

Systems -

16/06/2025

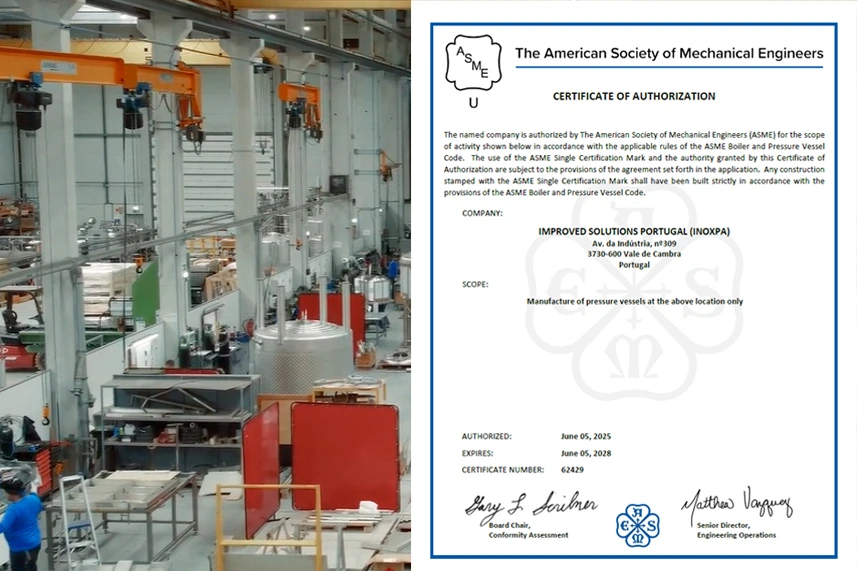

16/06/2025U-Stamp certification

This certification strengthens our position as a trusted supplier in industries where quality and compliance with standards is essential.