EHEDG

14/03/2014

EHEDG, the (European Hygienic Engineering and Design Group) is a European-based non-governmental organization devoted to the advancement of hygienic design and food engineering. EHEDG is a consortium of equipment manufacturers, food industries, research institutes and public health authorities, founded in 1989 with the aim to promote hygiene during the processing and packing of food products.

European legislation requires that handling, preparation, processing, packaging, etc. of food is done hygienically, with hygienic machinery in hygienic premises (the food hygiene directive, the machine directive and the food contact materials directive).

How to comply with these requirements, however, is left to the industry. EHEDG provides practical guidance on hygienic engineering aspects to help complying with these requirements. As food safety does not end at the borders of Europe, the EHEDG actively promotes global harmonization of guidelines and standards.

EHEDG publishes guidelines on different aspects of hygienic design and provides certification for industries on equipment used in the food industry.

INOXPA cares for all our customers and therefore we never compromise on quality standards and therefore we follow the guidance given by EHEDG in the hygienic engineering of our products. Inoxpa have its clients across the diverse range of industry from Food Processing, Pharmaceutical, Cosmetics and Dairy.

Some of the most common EHEDG product used in these industries is:

- Lobe Rotor Pump – HLR

- Centrifugal Pump DIN Food

Lobe Rotor Pump – HLR

The HLR pump is a rotary lobe pump designed in compliance with the EHEDG specifications for plants and processes that comply with the strictest hygienic requirements. Due to the low working speed, the rotary lobe pump is characterised by a gentle pumping and low shear of the product causing less damage possible. The rotary lobe pump is an ideal pump for the transfer of all types of liquids (from 1 to 1.000.000 cP) and liquids with solid particles (curd, biologic cultivations, etc.). The rotary lobe pump is adequate for the food-processing, cosmetic and pharmaceutical industries.

Centrifugal Pump DIN Food

The DIN-FOOD pump is a hygienic high capacity centrifugal pump (up to 1000 m³/h) designed to cater for an unfulfilled need in the food-processing and chemical and pharmaceutical industries. Its applications include processes in the brewing, dairy and beverage industries in general, as well as in ultra-filtering processes. It can also be used in the textile industry and in some specific processes in the chemical, cosmetics and pharmaceutical industries.

Contact

Other news

-

30/07/2025

30/07/2025Integral solutions that make the difference

INOXPA have been offering complete, customised solutions for years. We take care of the entire engineering, automation and assembly process.

Systems -

09/07/2025

09/07/2025CMC mixing systems

INOXPA’s CMC mixing systems are efficient, versatile, and customisable solutions for the dispersion of hydrocolloids across various industries.

Systems -

16/06/2025

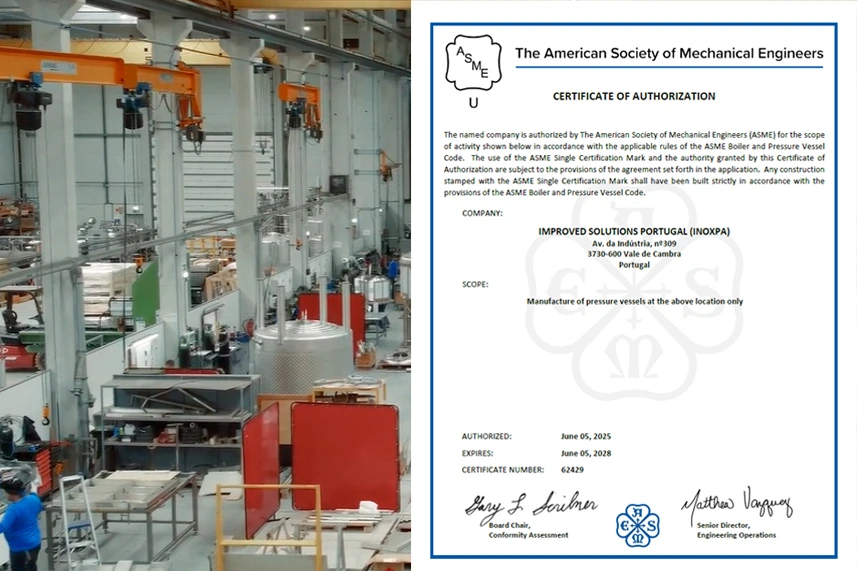

16/06/2025U-Stamp certification

This certification strengthens our position as a trusted supplier in industries where quality and compliance with standards is essential.