Divert Seat Valve K

08/05/2015

INOXPA is specialised in manufacturing of fluid handling equipment.

The divert seat valve K is a valve designed by INOXPA to handle liquid products in processes of the food-processing, pharmaceutical and cosmetics industries.

The divert Seat valve is a hygienic single seat valve which operates automatically by a single–acting or double-acting pneumatic actuator. By supplying compressed air, the shaft is moved to place the valve in the "open" or "closed" position. The 180º rotation of the pneumatic cylinder of single-acting actuators allows having a normally open or normally closed valve.

INOXPA designs and manufacturs the divert seat valve K with best quality material such as AISI 316L stainless steel for wetted parts whereas the other parts of the steel are made from AISI 304. Other features are EPDM gaskets, Ra ≤ 0,8 µm internal surface finish and bright polish external surface finish.

Salient Features of Divert Seat Valve K:

Compact and robust design.

Normally closed valve (NC) in the standard version.

The valve can be changed to normally open (NO) by simply reversing the position of the pneumatic actuator.

Standard connections: weld (mm or inches).

Available sizes: from DN 25 / 1" to DN 100 / 4".

Easy assembly/disassembly of internal parts by loosening a clamp fastener.

Open lantern allows visual inspection of shaft sealing.

360º adjustable body.

Applications of Divert Seat Valve K

Preparation of ghee.

Preparation of buttermilk.

Preparation of edible oil.

Preparation of milk.

Preparation of juice & other beverages.

Preparation of mayonnaise.

Contact

Other news

-

30/07/2025

30/07/2025Integral solutions that make the difference

INOXPA have been offering complete, customised solutions for years. We take care of the entire engineering, automation and assembly process.

Systems -

09/07/2025

09/07/2025CMC mixing systems

INOXPA’s CMC mixing systems are efficient, versatile, and customisable solutions for the dispersion of hydrocolloids across various industries.

Systems -

16/06/2025

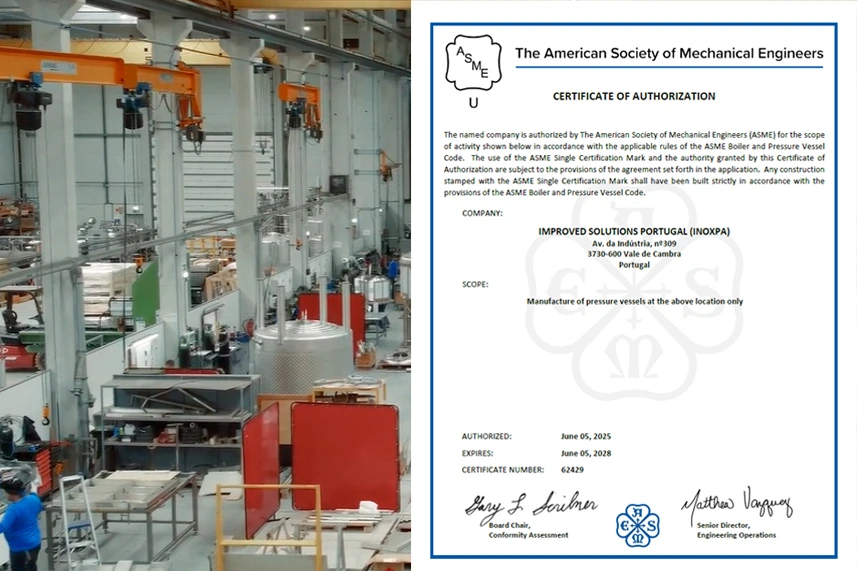

16/06/2025U-Stamp certification

This certification strengthens our position as a trusted supplier in industries where quality and compliance with standards is essential.