Customer Satisfaction Story

26/12/2012

INOXPA’s mixer proved to be more efficient and the energy consumption is reduced in comparison to :

|

Normal Homogeniser |

Inoxpa Inline Mixer |

||

|

Connected Load |

37 kw |

Connected Load |

1.1 kw |

|

Power consumption for two shift operation |

592 kw |

Power consumption for two shift operation |

17.60 kw |

|

Power Tariff for one day at INR 9/ unit |

INR 5328 |

Power Tariff for one day at INR 9/ unit |

INR 158 |

|

Expense for one year |

INR 19,44,720 |

Expense for one year |

INR 57,670 |

|

Savings |

Nil |

Savings |

INR 18,87,050 |

|

Cost of ownership of spare |

INR 2,00,000 |

Cost of ownership of spare |

INR 28,000 |

Customer was delighted to have the high level of performance parameters achieved through the mixer as promised by Inoxpa . In the month of October 2012, they decided to install Inoxpa’s Multi Tooth Mixer for better micron size of the product. The mixer is running successfully since the last three months with utmost satisfaction of customer.

Contact

Other news

-

30/07/2025

30/07/2025Integral solutions that make the difference

INOXPA have been offering complete, customised solutions for years. We take care of the entire engineering, automation and assembly process.

Systems -

09/07/2025

09/07/2025CMC mixing systems

INOXPA’s CMC mixing systems are efficient, versatile, and customisable solutions for the dispersion of hydrocolloids across various industries.

Systems -

16/06/2025

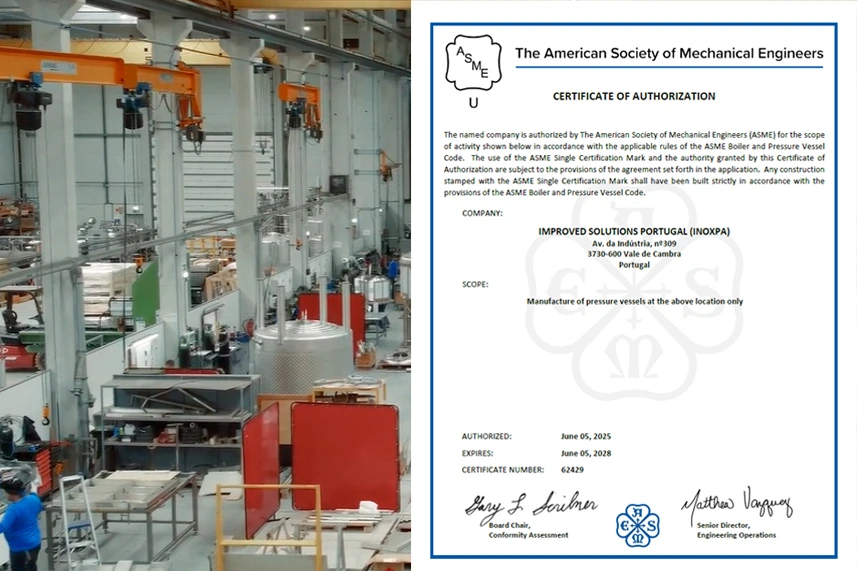

16/06/2025U-Stamp certification

This certification strengthens our position as a trusted supplier in industries where quality and compliance with standards is essential.