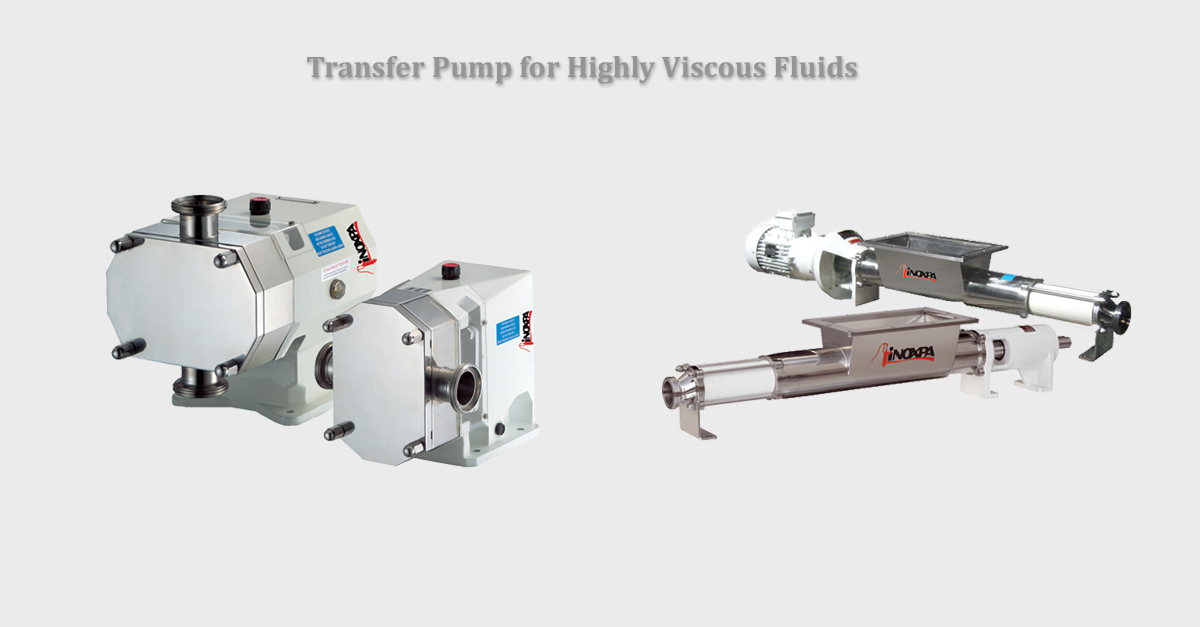

Transfer pump for highly viscous fluids

13/01/2016

High viscosity fluids due to their characteristics are thick in nature and need specially designed equipment to handle it with care. Viscosity often itself is a term which is defined and measured by the thickness of fluid. All around we can see many examples to understand the viscosity of fluid (hierarchically, from low viscous to high viscous fluid) such as: water, ethanol, olive oils, milk, glycerin, honey, gel, etc. These are form of fluids which differ in their viscosity and therefore require different fluid transfer equipment.

INOXPA is a leading brand in manufacturing of hygienic fluid transfer equipment for dairy, food, pharmaceutical and cosmetic industries. INOXPA has designed diverse range of pumps for fluid transfer of low viscosity, medium viscosity and high viscosity without altering fluid property.

For the transfer of highly viscous fluids, INOXPA has designed pumps which are widely used in fluid transfer application in the food processing, pharmaceutical and dairy industries:

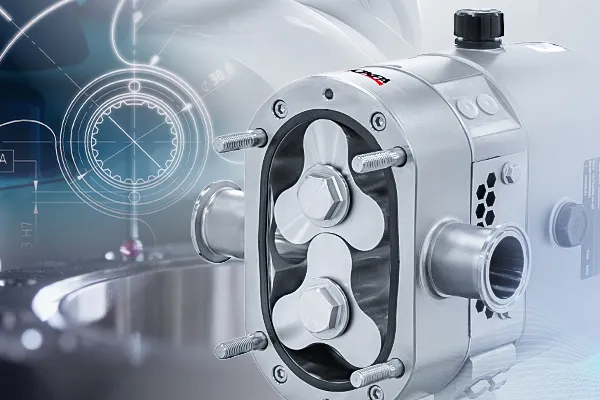

Rotary Lobe Pumps SLR, TLS and SLR-T:

Rotary Lobe pump is ideal for liquid transfer of high viscosity fluids such as ghee, glycerin, chocolate, marmalade, etc.

Progressive Cavity Pumps KIBER:

Progressive cavity pump KIBER is also designed to transfer highly viscous fluid.

KST-KSFT progressive cavity pumps, with a hopper at the suction side, help the feeding of viscous products inside the pump.

In case of query, feel free to write us at inoxpaindia.sales@inoxpa.com !

Contact

Other news

-

27/10/2025

27/10/2025Discover INOXPA’s Partner Portal: efficiency, simplicity and control

We present the Partner Portal, a platform designed to make two-way interaction between customers and INOXPA easier.

-

25/09/2025

25/09/2025UltiLobe: the ultimate lobe pump

UltiLobe is the new generation of rotary lobe pumps with hygienic design, that expands the INOXPA´s portfolio of positive displacement pumps.

Pumps -

30/07/2025

30/07/2025Integral solutions that make the difference

INOXPA have been offering complete, customised solutions for years. We take care of the entire engineering, automation and assembly process.

Systems