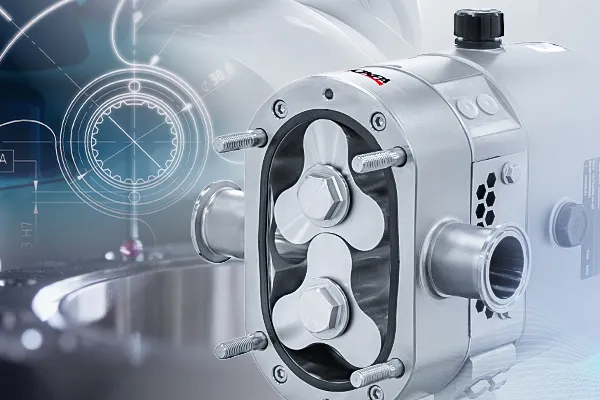

Progressive Cavity Pump KIBER

07/04/2017

.jpg)

A sanitary progressive cavity pump KIBER offers a solution to the wide range of applications in the food processing, dairy, beverages and personal care industry.

KS/ KSF operate on the principle of friction between the rotor and the stator which creates a vacuum in the inlet area and allow entry of the product in the pump.

Whereas, after the product filled in the pump, the rotor accompanies the product along the cavities created between the rotor and the stator up to the outlet.

Due to its design, KIBER progressive cavity pump is one of the most efficient solutions in the transfer of high and low viscosity products with or without containing solid particles.

The KS/KSF designed to provide maximum running hours comparable to other available products in the market.

KIBER pump can optionally be provided with different types of connections, mechanical seals, etc.

Benefit: The pump design makes itself self-priming and reversible.

Applications: ghee, butter, wine, concentrates, juice with pulp in dairy and beverages; jam, jelly, oil, pate in food processing; soaps, gels and creams in the personal care industry.

Contact

Other news

-

29/01/2026

29/01/2026PIG product recovery systems: Sustainable savings

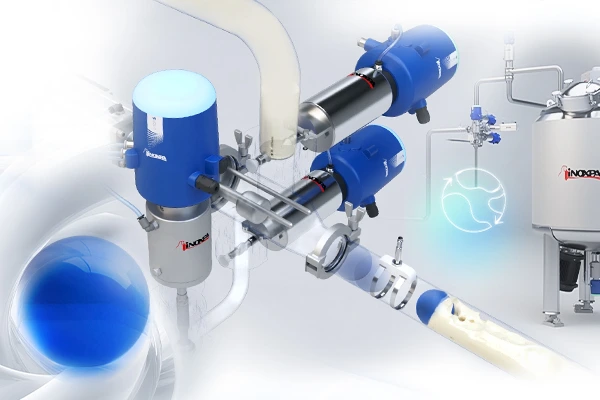

INOXPA PIG systems recover up to 98% of the product, reduce water consumption and optimise industrial processes with automated technology.

Systems -

27/10/2025

27/10/2025Discover INOXPA’s Partner Portal: efficiency, simplicity and control

We present the Partner Portal, a platform designed to make two-way interaction between customers and INOXPA easier.

-

25/09/2025

25/09/2025UltiLobe: the ultimate lobe pump

UltiLobe is the new generation of rotary lobe pumps with hygienic design, that expands the INOXPA´s portfolio of positive displacement pumps.

Pumps