Pasteuriser HTST

20/01/2017

.jpg)

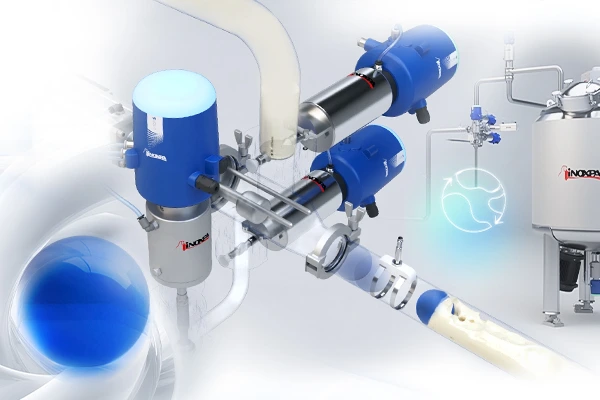

INOXPA Pasteurisation Unit (HTST) is designed for the thermal treatment of milk and dairy products as well as other food products as soft drinks and juices. The process destroys pathogenic microorganisms by heating the product to a moderately high temperature for a brief period.

Pasteuriser is a device used to pasteurise and treat food products to kill micro organisms such as bacteria. Pasteurization can be carried out by means of:

- HTST or Flash Pasteurization – High Temperature & Short Time

- Ultra Heat Treatment

HTST or Flash Pasteurization

It is one of the most common methods in which the product is kept at high temperature for a brief period to kill bacteria before instant cooling. The technique is used to obtain the expected million reductions in the number of microorganisms in the particular food product.

Ultra Heat Treatment

In Ultra Heat Treatment process the food item is heated to 265° F for 0.5-1.5 seconds; which can render foods so stable that they can be stored at room temperature in aseptic containers for several months.

HTST or Flash treatment is the most common process used by the Dairy, Food and Beverage Industry because of it’s certain characteristics like energy efficient; minimize damages to the food items and to efficiently destroying microorganisms.

Milk, Dairy Products, Juice and some other food items most commonly used in the process of pasteurization to extend their life and to store.

Operating principle

The product arrives to a balance tank (BTD) and is pumped to a plate heat exchanger. It is heated to a pasteurising temperature that depends on the type of food product and/or process requirements. Next, the product passes through the holding tube that ensures the correct pasteurisation by holding the product at the required temperature for the specified period of time.

If the heat exchanger has a regeneration stage, the treated product is used to preheat the feed material, losing heat in the process, this, reducing the energy required to reach the pasteurising temperature and in reducing the cooling required.

Finally, the product is cooled to 4 ºC for cold filling or storage in isothermal tanks.

If, due to any problem, the pasteurising temperature is lower than the required one, an automatically operated flow divert valve sends the product back to the balance tank (BTD), thus, preventing any microbial contamination of the final product.

Applications

1. Preparation of pasteurized packet and bottled milk.

2. Preparation of packaged juices.

3. Preparation of canned foods.

4. Preparation of syrups, vinegar, wines etc.

Read here for more details:

Contact

Other news

-

29/01/2026

29/01/2026PIG product recovery systems: Sustainable savings

INOXPA PIG systems recover up to 98% of the product, reduce water consumption and optimise industrial processes with automated technology.

Systems -

27/10/2025

27/10/2025Discover INOXPA’s Partner Portal: efficiency, simplicity and control

We present the Partner Portal, a platform designed to make two-way interaction between customers and INOXPA easier.

-

25/09/2025

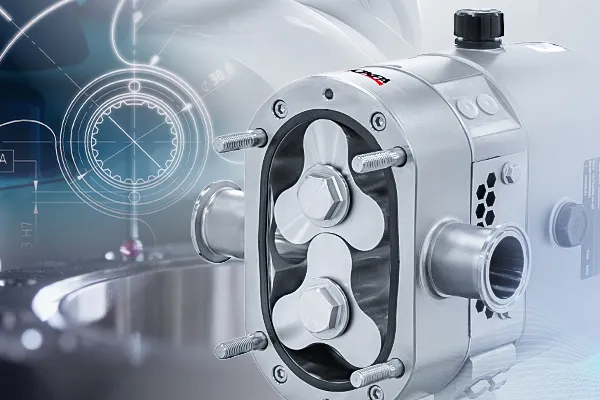

25/09/2025UltiLobe: the ultimate lobe pump

UltiLobe is the new generation of rotary lobe pumps with hygienic design, that expands the INOXPA´s portfolio of positive displacement pumps.

Pumps