Global Pharma Industry Eyeing

12/12/2013

World is looking at India for front-end manufacturing solutions, contract research and machinery and technologies, according to UBM India, the organiser of CPhI 2013, which was held along with other concurrent events P-MEC, ICSE and BioPh India in Mumbai from December 3-5, 2013.

Pharma industry has proceeded and progressed to encourage this industry in India to invest in Egypt. This kind of mutual cooperation and investment is very beneficial to both the sides but not just interested in imports of final product but to manufacture the product in Egypt. The focal point to export to the whole MENA (Middle East and North Africa) region will be a win-win situation for both sides and we will do our best to help this push,” Amrasad, Head of Egyptian Pharmaceutical Vigilance & Egyptian Ministry of Health, a visitor at CPhI exhibition, was quoted in the press release

India is on a major growth plan and the authorities are offering required facilities for the overall growth in the pharma industry. For example Andhra Pradesh, which boasts of 25 per cent of the country’s pharma production, is planning major expansion. “We are proposing two more SEZs for the pharma industry in the state to provide major boost to the exports of bulk drugs,” said G Dharmadata, Joint director of Drugs Control Authority of Andhra Pradesh.

Looking at the speedy developments taking place in the industry at present the $18 billion industry is poised to grow manifold to $55 billion by 2020. But, industry (especially the ingredients and pharmaceutical machinery manufacturers) should be ready to face competition from China and other Asian countries. Ajit Singh, Chairman, ACG Worldwide, said, “Indian Manufacturers are good in what they are doing and they are moving up the value chain. This may not last long and we may need to rediscover ourselves in the next 3-5 years. China, who is currently too occupied in satisfying its internal demand, would be a serious contender on cost and quality in the near future. Indian manufacturers will have to get prepared for that scenario.”

ME 800X & ME 1100

ME 800X

The 800X series multitooth mixers are employed in the applications requiring high shear for achieving a thorough emulsification. Until now mills and homogenizers have been used for production of high quality emulsions.

Among the products that can be prepared with this mixer there are High quality body care products, pharmaceutical and veterinary solutions.

Design and Features

- High shear. Particle size reduction to less than 1 micrometer.

- Tip speed upto 50m/s

- Sealing system: sanitary single cooled mechanical seal.

- Adjustment of different tolerances between the rotor and stator.

- CIP compatible design

- Standard connections: Clamp ISO-2852

- Assembly with pulleys and belts

- Clamp drain port

- Motors: IEC B35, IP 55, F Class Insulation, 3000rpm.

ME 1100

The ME 1100 vertical high shear mixers present a solution for the processes of dispersion, emulsifying, homogenisation and disintegration of solids in a wide range of products in the pharmaceutical industry.

Design and Features:

- High Shear, Particle size reduction to less than 100 microns.

- V-ring

- Slotted Head (Standard)

- Possibility to replace the stator and the bushing without disassembling the mixer

- Various types of interchangeable heads.

- Motors: IEC B5, IP55, F-Class Insulation

Contact

Other news

-

27/10/2025

27/10/2025Discover INOXPA’s Partner Portal: efficiency, simplicity and control

We present the Partner Portal, a platform designed to make two-way interaction between customers and INOXPA easier.

-

25/09/2025

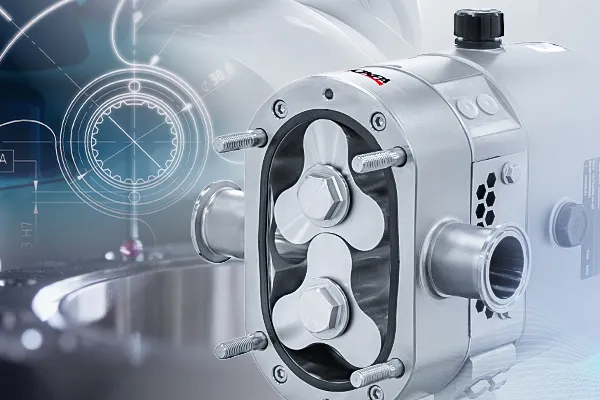

25/09/2025UltiLobe: the ultimate lobe pump

UltiLobe is the new generation of rotary lobe pumps with hygienic design, that expands the INOXPA´s portfolio of positive displacement pumps.

Pumps -

30/07/2025

30/07/2025Integral solutions that make the difference

INOXPA have been offering complete, customised solutions for years. We take care of the entire engineering, automation and assembly process.

Systems