Gel mixing

03/02/2016

.jpg)

Gel is a thick substance of high viscosity like jelly. Its basic component is liquid that is mixed with other ingredients such as gelatin.

Due to its property, the preparation of gel requires specific equipment.

INOXPA manufactures equipment for the food-processing industry that specifically meets the requirements of highly viscous fluid applications.

Solution offered by INOXPA to one of our customers in South Africa can serve as example.

The customer required a hygienic and effective solution for gel mixing.

The skid designed for the process was equipped with 2 tanks of 300 L where one was for mixing and the other was vacuum tank, scraper agitator, BMI agitator, in-line mixer ME4100 and progressive cavity pump KSF30.

Description of the process: the mixture tank is filled with water, the scraper agitator is turned on, powder is added into the tank and the BMI agitator with cowles is started. During the process, the product is circulated through an in-line mixer ME4100 via a progressive cavity pump KSF30 for 30 minutes.

Soon after the preparation of mixture (12000 CPs), it is pumped over to the vacuum tank. The scraper agitator is turned on and the vacuum pump is started to reach 5 mBar.. After running it for 30 minutes, the gel is pumped to the extruder unit whereas another batch of gel mixture is then entered into the vacuum tank.

For safety reasons, INOXPA provided the option of safety interlock that turns off the agitator in case one of the manholes is opened.

For more details or product enquiry, please write to us at inoxpaindia.sales@inoxpa.com!

Contact

Other news

-

27/10/2025

27/10/2025Discover INOXPA’s Partner Portal: efficiency, simplicity and control

We present the Partner Portal, a platform designed to make two-way interaction between customers and INOXPA easier.

-

25/09/2025

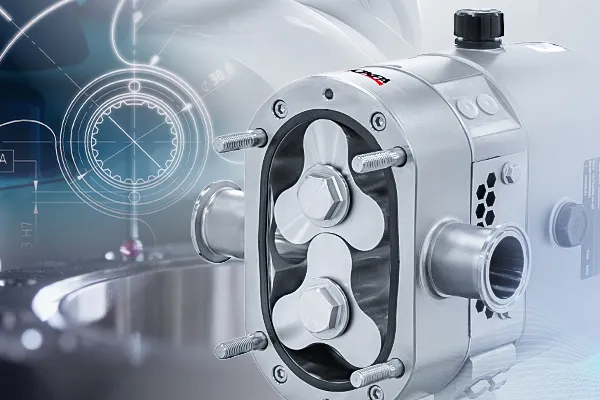

25/09/2025UltiLobe: the ultimate lobe pump

UltiLobe is the new generation of rotary lobe pumps with hygienic design, that expands the INOXPA´s portfolio of positive displacement pumps.

Pumps -

30/07/2025

30/07/2025Integral solutions that make the difference

INOXPA have been offering complete, customised solutions for years. We take care of the entire engineering, automation and assembly process.

Systems