Agitators for standard tanks

15/03/2017

Agitators are the most common equipment used for preparing liquid-liquid or solid-liquid mixtures or solutions.

Depending on applications, tanks with rounded bottoms or with conical bottoms are used.

Product viscosity plays an important role in deciding the perfect agitator equipment for the application.

INOXPA has a wide range of agitators for different applications and requirements

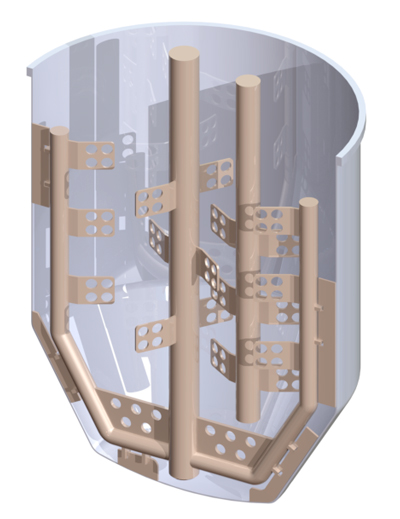

1. Anchor-type agitators

These agitators are designed for applications with highly viscous products and / or Non – Newtonian fluids. Different types of anchor are available.

2. Propeller-type agitators

These agitators are best designed to work on low viscosity products for suspension, dispersion and homogenization with the control to operate agitators at low, medium and high speed.

Propellers are axial flow agitators, ideal for solid-in-liquid solutions or suspensions because they prevent solid particles from depositing on the bottom of the tank.

3. Blade-type agitators

Blade agitators are ideal for suspension, dispersion and homogenization processes with low and medium viscosity products. Agitators are designed to operate at a low to moderate mixing speed. Blades are axial flow agitators, ideal for solid-in-liquid solutions and suspensions. They are also recommended for mixing liquids.

4. Turbine-type agitators

Turbine agitators are used in emulsification and dispersion processes which require operation at very high speeds. They are efficient across a broad range of viscosities with a highly effective mixing capacity.

For more information on product, please write to us at inoxpaindia.sales@inoxpa.com !

Contact

Other news

-

29/01/2026

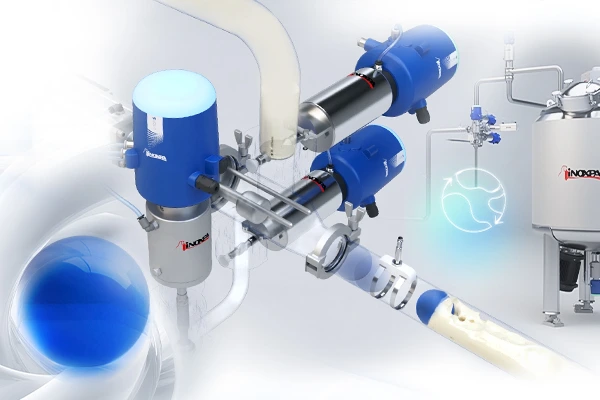

29/01/2026PIG product recovery systems: Sustainable savings

INOXPA PIG systems recover up to 98% of the product, reduce water consumption and optimise industrial processes with automated technology.

Systems -

27/10/2025

27/10/2025Discover INOXPA’s Partner Portal: efficiency, simplicity and control

We present the Partner Portal, a platform designed to make two-way interaction between customers and INOXPA easier.

-

25/09/2025

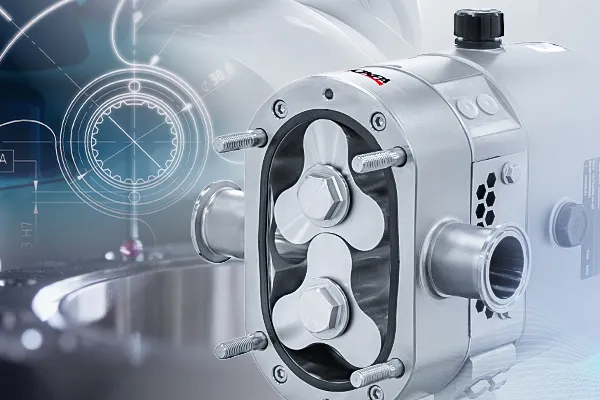

25/09/2025UltiLobe: the ultimate lobe pump

UltiLobe is the new generation of rotary lobe pumps with hygienic design, that expands the INOXPA´s portfolio of positive displacement pumps.

Pumps